Oil Analysis Programme

Many OEMs and their service companies use EA’s oil analyses programme as an indispensable part to follow the health of their equipment and to determine planned and predictive maintenance strategies.

All with the main goal to reduce equipment downtime through early diagnosis of potential failures, to reduce repair costs and technician time, to reduce oil costs by maximizing the oil drain interval and to notice changes in e.g. gas qualities when using bio- or special gasses with gas engines or compressors.

After sending your oil samples to one of our laboratories, you will not only receive a report with the measurement data and trends, but you will also receive from our technical experts an advise how to act based upon the data, the history of your equipment and your specific application.

If you want to make use of our oil analysis programme, please contact us.

We will be pleased to set up the oil analysis programme for you.

Technical Advice & Problem Solving

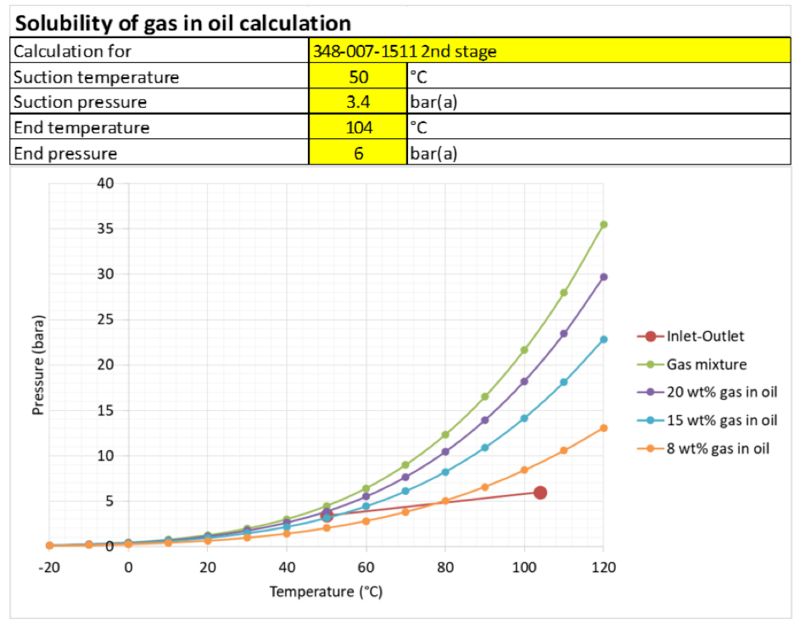

Thanks to our engineer’s in depth knowledge and long term experience with several equipment such as gas engines, compressors, vacuum pumps, …and several applications (different types of gasses, environmental conditions, …, we actively support our customers with solving a wide range of equipment and application related challenges. Both during the development, commissioning or operation phase of the equipment or system package.

Whether you want to solve a technical problem, be able to operate under extreme conditions, reduce costs by extending oil drain intervals or reducing fuel consumption, reduce environmental impact and/or reduce the amount of different lubricants in use in your organization, our technical experts are there to analyse your challenge and offer you the best lubrication solution.

One of the services our customers highly value is that we go beyond our lubrication expertise when giving technical advice and support with problem solving.

They appreciate the close and direct contact with our engineers and technical experts, which they do not experience when working with large oil corporates. Because our engineers are also trained and experienced in Analytical troubleshooting, Statistical Process Control and 8D methods, we also give our customers advise when we notice that the root cause is not related to lubrication, which is a unique service.

If you want technical advice or want to solve an actual problem, please contact us.

We will be pleased to help you.