Wire rope, chain & cable

View productsECO HTE

CABLE LUPROMAX-CCL

WIRE ROPE LUBRICANT LOW VISCOSITY

WIRE ROPE LUBRICANT HIGH VISCOSITY

ECO HTE

Synthetic

ECO HTE is a synthetic, high performance ester based oil which has been specially formulated for the food industry to lubricate drive and transport chains at elevated temperatures. It is based on an advanced blend of synthetic fluids and selected additives chosen for their ability to meet the stringent requirements of the food and beverage industry. Certifed by NSF for ISO 21469 and registered by NSF (Class H1) for use where there is potential for incidental food contact. Produced according to FLT Quality Standards, in facilities where HACCP audit and Good Manufacturing Practice have been implemented and form part of the quality and hygiene management systems ISO 9001 and ISO 21469.

CABLE LUPROMAX-CCL

CABLE LUPROMAX-CCL is a water-based clear cable pulling lubricant specially developed to eliminate the mess and staining caused by the conventional oil based lubricants. It is compatible with all common cables, including polyethylene jackets, and does not pollute the environment as it evaporates after use. CABLE LUPROMAX-CCL is non toxic and does not cause any harms to applicators. CABLE LUPROMAX-CCL exhibits good friction reducing properties and does not cement-in cables. It is non-flammable and eliminates all potential fire hazards as compared to wax-based cable pulling lubricants.

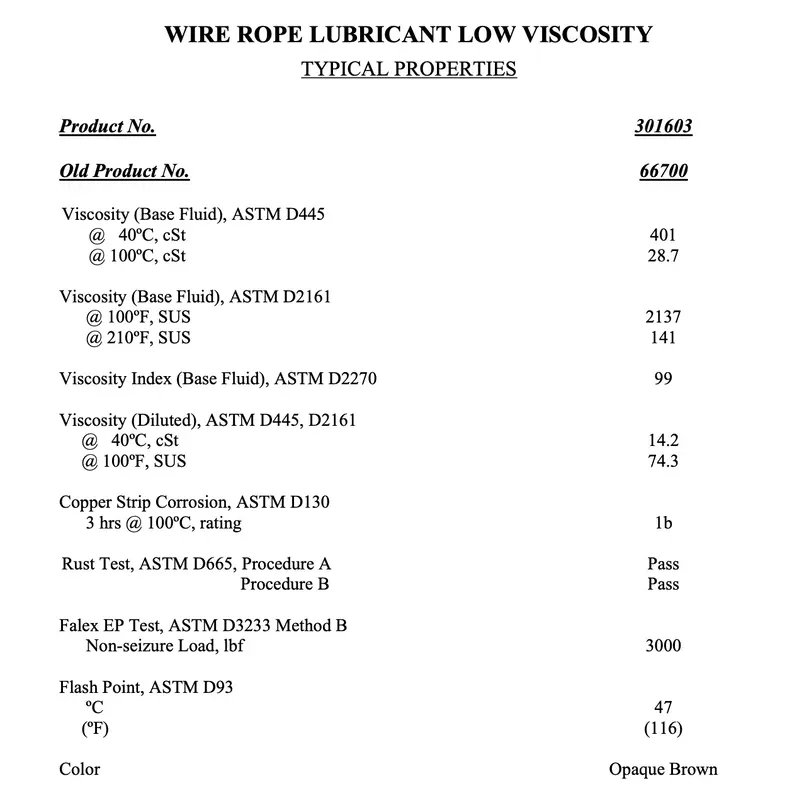

WIRE ROPE LUBRICANT LOW VISCOSITY

Sythetic

Wire Rope Lubricant Low Viscosity, commonly known was EA Wire Rope Lubricant, is specially formulated for ropes requiring a penetrating lubricant. Wire Rope Lubricant Low Viscosity’s penetrating action draws the lubricant to the core, coating the inner strands, protecting them from rubbing wear and corrosion. Wire Rope Lubricant Low Viscosity exhibits superior water displacement to provide a positive film, even on wet ropes. The anti- wear and anti-corrosion properties protect the wire rope inside and out, as well as protecting sheaves and drums. Applications Mining - dragline drag and hoist ropes, drift ropes, crane cables, winch ropes and tow cables Marine - tug tow ropes, shipboard crane cables and winch ropes Features and Benefits All-season Water displacement Semi-dry film Anti-wear properties Corrosion inhibited General Description Has a useful application temperature range of -46°C to 60°C (-50°F to 140°F). No need to change grades as temperatures fluctuate. Proprietary water displacing agent allows for relubrication directly on to wet ropes. Being non-sticky in nature, will not attract dirt, dust or other abrasive contaminants. Provides extended rope life and added serviceability to sheaves and drums. Protects ropes from internal rust and subsequent strand failure. Wire Rope Lubricant Low Viscosity contains a powerful water displacing agent to facilitate application directly on to wet ropes. It provides excellent adhesive properties, reducing consumption, and has high load carrying additives to extend rope life. The inclusion of inhibitors reduces corrosion and rust. It can be applied manually or through most automatic lube systems.

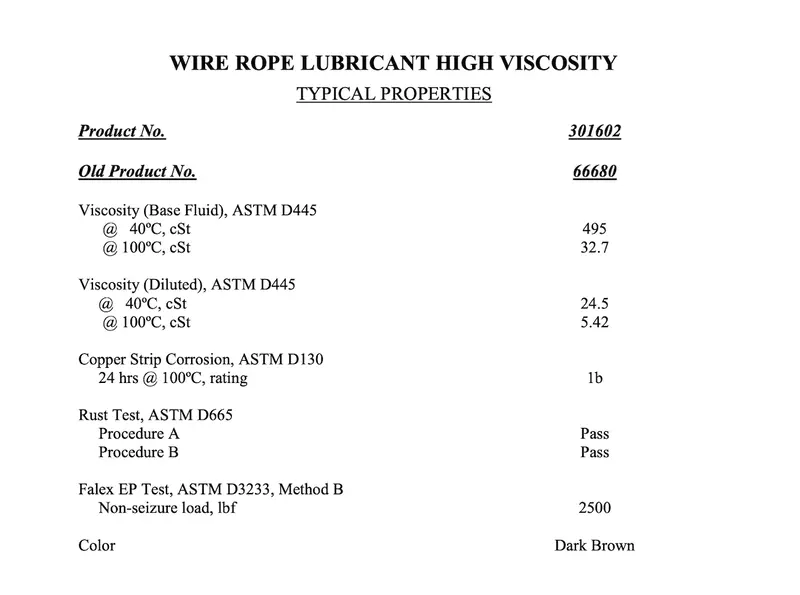

WIRE ROPE LUBRICANT HIGH VISCOSITY

Sythetic

Wire Rope Lubricant High Viscosity, commonly known as EA Wire Rope Lubricant 999, is specifically formulated to provide maximum rope, sheave and drum protection while remaining extremely cost-effective. It is an environmentally friendly alternative designed to replace the use of waste oils. Its anti-wear and corrosion inhibiting properties provide protection for year round use inside and out of the wire rope. The water displacement characteristics ensure that any water seeped into the rope core will be pushed out and replaced by Wire Rope Lubricant High Viscosity for total protection. Applications Mining - dragline drag and hoist ropes, sheaves, drums and pennant lines. Shovel hoist ropes Marine - port crane cables, shipboard cranes and tug tow cables General - most crane cables and tow cables Features and Benefits All-season Economical Excellent protection Water resistant General Description Designed for year round application with a useful temperature range of -34°C (-30°F) to 60°C (140°F). Penetrating ability protects interior strands, increasing rope life. Provides excellent corrosion, rust and wear protection to reduce premature rope failure or fatigue. Provides excellent water repellence, giving protection under the most inclement conditions. Wire Rope Lubricant High Viscosity is designed as a penetrating lubricant that provides maximum rope, sheave and drum protection while remaining extremely cost effective. It is formulated with an exceptional chemical Extreme Pressure system and rust and corrosion inhibitors with excellent water displacement characteristics.